GENERAL MOTORS HIGH ENERGY IGNITION (HEI) SYSTEMS

THEORY OF OPERATION

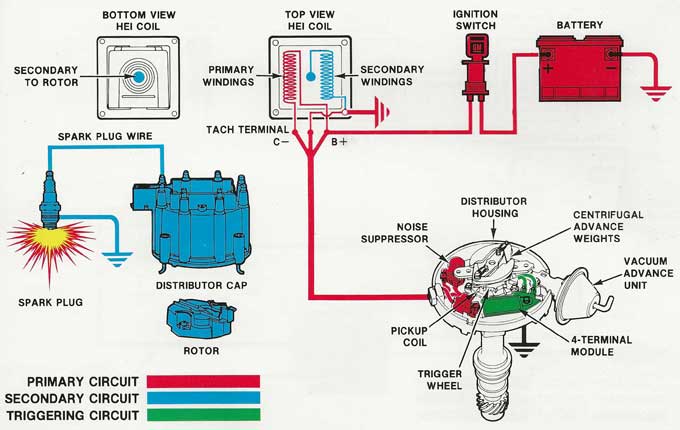

General Motors Standard High Energy Ignition (HEI) system, shown above, is constructed differently than other electronic ignition systems because all the components are contained within the distributor. The HEI distributor consists of an electronic control module, a pickup coil assembly, a trigger wheel, rotor, a large distributor cap, vacuum and centrifugal advance mechanisms, a high energy coil (mounted in cap) and a capacitor for noise suppression. As with most electronic systems the HT leads are slightly thicker (generally 8mm min) and made of a higher grade material to withstand the high voltage produced during the ignition process.

As the distributor shaft rotates and the trigger wheel tooth approaches the pickup coil, a trigger signal is generated and transmitted to the control module. The control module in turn switches its power transistor on to allow current flow in the primary of the coil. As the trigger wheel tooth passes the pickup coil, it transmits another trigger signal to the control module to switch the power transistor off. This interrupts the current flow in the primary of the coil and collapses the magnetic field. As the field collapses, a high voltage is induced into the secondary circuit to fire the spark plugs.

Note that the terminals on the distributor cap are similar to the terminal ends on the spark plugs. This is a common feature on a few HEI systems like the Holden WB 6 & 8 cyl engines and later commodores.