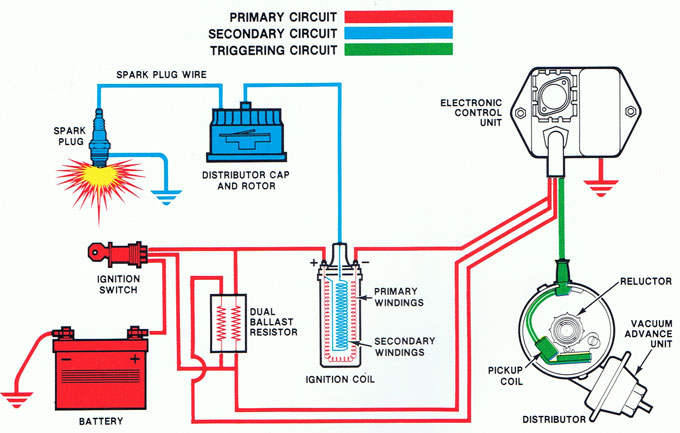

O.E variable dwell electronic systems represented a significant leap forward in ignition technology at the time. The distributor for these systems discards the conventional points and replaces it with a reluctor assembly and control module. The reluctor comprises of a permanent magnet with as many pole pieces as cylinders in the engine, a pick up coil with inductive wiring and a trigger wheel. The trigger wheel is comparable to the breaker cam of the contact breaker system. The number of teeth on the trigger wheel also corresponds to the number of cylinders in the engine. The signal created by this induction type pulse generator is the basis from which the on time of the dwell angle is determined by the control module. Consequently, this type of system is usually known as variable dwell. It allows a higher primary current to pass to their particular ignition coil, creating good intensity, combined with a long duration spark, to achieve greater total spark energy throughout the entire RPM range. These distributors continued to employ conventional mechanical and vacuum advance, the same as points systems. The location of the control module in some models have been miniaturised and are housed in the distributor body.

The ignition coil used for these systems is specifically designed to cope with their variable dwell operation. They employ greater primary and secondary windings as compared to points type coils, and would burn out points if used in such a system. Original versions used either an oil filled design (and looked similar to points coils, but sometimes employed a male high tension tower), or were of a transformer design.