If your going to attempt to tune your car at home then there are some tools you will need to help you get the job done. Not all are necessary as some of the other tools will do the job but will require extra skill and attention to accomplish the same result. Apart from the tools below you will need a selection of screwdrivers and spanners. There will of course be some specialty tools you may need that pertain to your make of vehicle. If you can't afford them or can't find a work around then you will need the services of a mechanic who has the tools to do the job.

|

|

The good old 12v test light. DO NOT use this on electronic circuits. Only a high impedance multimeter can be used here or a digital circuit test light. This is the device you will use when static timing the engine. A multimeter can be used but the test light is better. You can use it to probe wires to check for voltage if you can't get a bare connection, but be mindful that you are penetrating the insulation of the wire and therefore could potentially have problems down the track. |

|

|

Obviously a timing light is high on the list. A cheap timing light will suffice but buying a more expensive unit will give you extra features. With a timing light you can check: centrifugal advance is within specs.. vacuum advance is within specs detect distributor drive gear play or timing chain play and if your clever you can check for bent distributor shaft or worn dist cam lobes, but this will require you to precisely mark your harmonic balancer. |

|

|

A multimeter is invaluable and the main readings you will use is resistance and voltage. All electrical devices have resistance and need to be within specifications for them to operate correctly. eg. the primary & secondary winding resistance in the ignition coil and the resistance of carbon HT leads. What about the resistance between the chassis earth and the engine or the battery. A high resistance here has implications to the entire electrical system. Voltage another important measurement. eg. Battery voltage, battery voltage during engine cranking, voltage to electrical components. If the correct voltage is not supplied then obviously the component won't work properly. |

|

You will need a dwell & tacho. This one is $50 bucks from Super Cheap. It is also a multimeter so you have two tools in one and therefore you won't need a separate multimeter as above. |

|

feeler gauges a must item. I use them so much that I have to replace them every year. |

|

|

As you may have read, I am not a fan of these anymore since I purchased an ultra-sonic stethoscope. Well I guess you won't have one of those so this is your best option. When using one to find vacuum leaks make sure you place the open end of the tube as close as you can to the areas you are testing otherwise you may miss the sucking sound you are searching for. When all else fails there is another very popular method of finding a vacuum leak and I discuss this method in my article on vacuum in the Tuning section. |

|

|

When working with late model cars using various sensors this device is magic. It is a resistance wheel and can be purchased from an electronics store for about $20. It can be used to replace a faulty coolant or air temperature sensor. Try dialing in a different air temperature and feel the difference in horsepower. If you suspect a sensor is faulty, plug this in, dial up the correct resistance and see if the engine runs correctly. If it does the sensor is faulty. Read my story in the 'From the Archives' section on how I used this to find the problem. |

|

|

A real cheap infra-red temperature gun. Handy for many things. Checking radiator cooling efficiency, finding hot spots in the engine block or cylinder head which indicates poor coolant flow or restriction. Check intake or exhaust runners for even temps or even the transmission temp or diff temps. |

|

|

I use these leads a lot when testing electrical & electronic devices, either while the device is still on the car or if I remove them and want to bench test. About $8 from an electronic store. |

|

|

If you have multiple carbs then you must have a flow meter. This one actually measures the air flow through the device in Kilogram per Hr. Another type I have used is to the right and is very good also. I do not accept that anyone can balance a set of triple carbs with a conventional stethoscope. Here is a comment I found on a forum - Years ago, I tried the 'ol "hose-in-the-ear" trick (with the other end in the

carb throat) to try to balance my SUs. I must be tone-deaf because

when I plopped on my Uni-Syn carb balancer - I was really off the

mark! |

|

A compression tester for testing the compressions in your motor. Over the last 30 years I have only used one of these about 10 times. The reason being is that with an oscilloscope and vacuum gauge and other specialised equipment I can diagnose the problem without having to perform an actual physical test. The customers wanted to know the actual compression, so one of these is the only way to know this. Obviously for the do-it yourselfer this will be a good tool to have. |

|

This is a vacuum pump & gauge combo. This is used to test vacuum devices and very handy for setting power valves correct setting during carby o/hauls. This may be a little expensive for a week-ender. |

|

This vacuum gauge is a reasonable quality and has indications around the face of the gauge as helpful hints. Vacuum plays a vital part in the engines operation and efficiency. This tool is a must. |

|

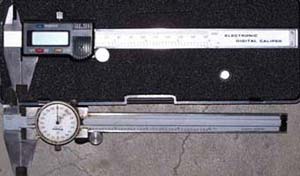

Vernier calipers. A new digital will set you back $30 or less. The dial vernier I have goes back to the early 80's. Both are very handy for setting up multiple side draft carby jets and any measuring you need to do. |