|

Suits Models:

Ford Bronco & XLT 1981-85 5.8L

Ford F100 F350 F500 F600 1977 on 5.0L 5.8L

Falcon GTHO XC - Cobra 1976-12/78 5.8L 351ci

Fairlane ZF ZG ZH ZJ ZK 302/351ci

Falcon Fairmont XA XB XC XD XE 1976-3/83 302/351ci

LTD ZH ZJ 5/76-77 351ci

LTD FC FD 6/79-3/83 302/351ci

|

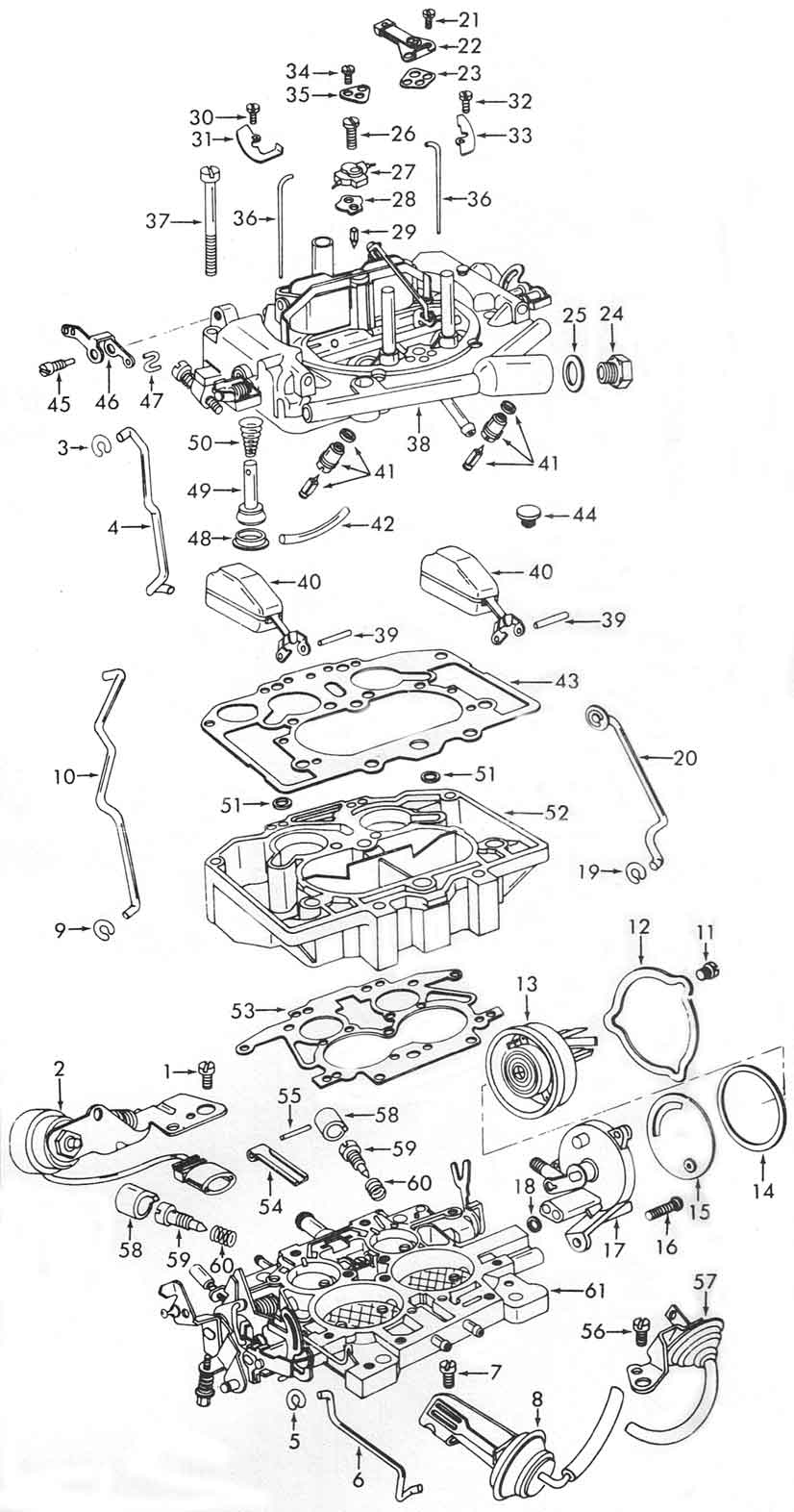

This huge carb came out on the Ford V8's, 302 & 351. Not that difficult to re-build, but it needs to be adjusted correctly to do a satisfactory job. Unfortunately this is not the case in many rebuilds, so the carby got chucked in favour of a 600/650CFM Holley carb, with no real advantage gained. In my opinion it is easier to adjust a Thermoquad than a Holley. For the stock engine to a mild performance re-build, you should consider keeping the TQ. Just make sure you find a tuning specialist in

your area that knows how to adjust and modify it. The instructions that come with a Fuel Miser carb kits do not have all the critical linkage adjustments anymore as it once did. You will need a factory service manual to accomplish this.

|

.jpg)