|

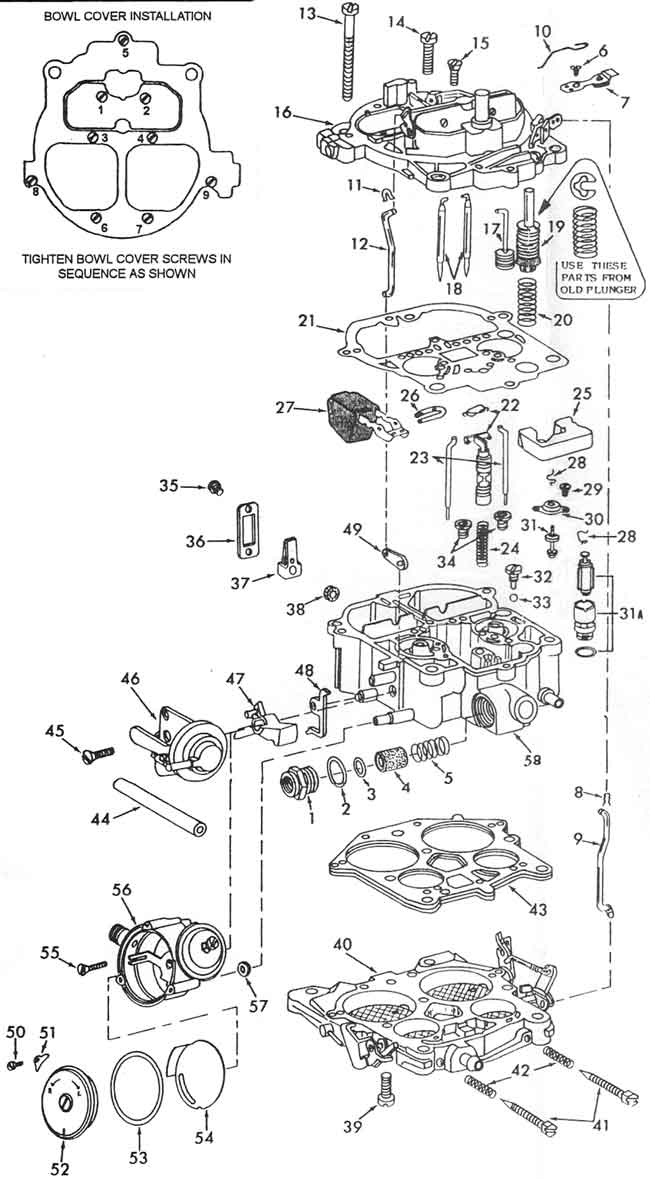

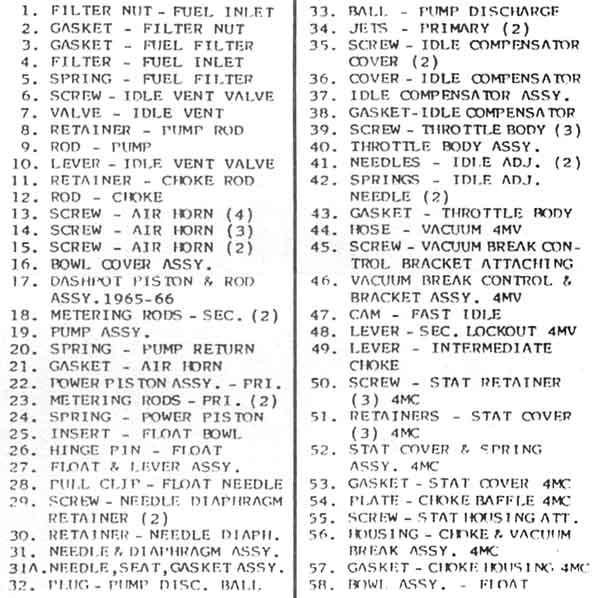

Rochester Quadrajet 4MC 4MV |

|

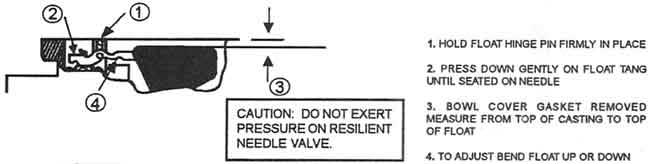

Typically fitted to the Holden, GM range of V8's, early style which has the mixture screws exposed so they can be adjusted. There are many variations to the design but they are only minor changes to accommodate extra emission hoses and each model will of cause have different jetting and slightly different adjustments. These carbies are also misunderstood and therefore were turfed for a Holley spreadbore 650 or squarebore 600. To adjust the float level, the air horn is removed. You need to hold down the float pin retainer while lightly pressing on the float against the needle & seat. Measure from the top of the float approx 1mm from the toe end of the float to the top of the casting gasket surface of the body without gasket in place. The measurement is 6.35mm or 1/4". If you use the Fuel Miser carb kit, the correct specification will be written on the instruction sheet. Get rid of any paper fuel filter fitted in the inlet fitting and fit a decent one in the fuel line between the fuel pump & the carby. A common problem is the inlet fuel fitting gets stripped after multiple removals. A thread repair fitting was once available but I have not seen any available recently. The top air horn usually has a warp and needs very careful and skilled hands to straighten it along with the matching surface of the main body. This is very time consuming and to be perfectly frank, if the surfaces are worn badly, then throw the carb away. The cost to straighten the parts would run into hundreds of dollars in the hands of a specialist carb rebuilder. This carb uses tapered needles into main jets in both the primary & secondary barrels, similar to an SU. The correct adjustment of these needles is critical to the proper operation of this carb. It is even more critical when used on a modified engine. Another problem these develop over the years is fuel leaking from the fuel bowl overnight. The engine starts in the morning but quickly dies until the fuel pump fills the fuel bowl to allow for the accelerator pump to pick up some fuel to squirt it into the motor for starting. The easiest way to handle this is to JB Weld it. The next photo shows the main body inverted with some JB Kwik Weld already applied to the fuel gallery plugs. This stuff will seal the leaks if present forever. There are 6 gallery plugs that you can seal. Maybe not all are leaking but while your there mixing up the JB you may as well seal them all. Be careful when sealing the 2 big plugs. Don't let the JB ooze over the sides. The base just fits over the edges of the cylinders so if you widen them the base will not fit down correctly. Also don't pile the JB up to high as it will bottom out in the base and once again the gasket will not compress correctly and you also run the risk of cracking the base when the carby gets all tightened down. As a side note, JB Kwik working time is a few minutes, so don't muck about, get it on and smoothed over before it gets to stiff to work with.

|

|

|