|

Rochester Varajet II |

|

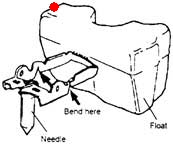

This was not the most popular carb choice that Holden ever made, at least not with many mechanics. It is fitted to the Camira, Holden4 star-fire engine and Holden6 Blue engine. Two sizes were available - 28mm venturi giving you 375cfm and 30mm venturi for 397cfm Common faults with these were:

According to the manufacturer, once the throttle shafts are worn, the base needs to be replaced, however these shafts can be purchased aftermarket in oversize and replaced by an experienced carb re-builder. Replacing the secondary shaft required grinding the connecting linkage from the shaft and then silver soldering the fitting onto the new shaft. If this job is not done with the utmost precision with the shafts and discs positioned correctly in the bores, the carb will be unstable at idle. Anti run-on solenoid. (23) Its function is to ensure the engine stops when turned off at the ignition key. On late model vehicles with higher idle speeds this item is required, otherwise the engine may kick over with pre-ignition for a little bit after switch off. There are two types of anti run-on solenoids.

If a very thick compressible base gasket is used under these carbs, DO NOT over tighten the base nuts as this will result in cracking the carby base, but generally a bakerlite plate is used with thin gaskets on either side. The primary & secondary disc position, the idle by-pass adjustment and mixture screw must all be adjusted exactly to manufacturers specs for this carby to perform at its best. Unfortunately in most cases the first thing to get incorrectly adjusted is the low speed screw which changes the throttle disc position in the bore and this has a roll on effect with the other adjustments. There are various other linkage adjustments that need to be checked and corrected. It is best to get the specific workshop manual for your vehicle to accomplish this. If the throttle shafts have lateral movement then have them replaced. All that said though, I can say that this carb when operating correctly will outperform a weber conversion easily, mainly because this carb is a spreadbore and has the best of both worlds, in reasonable economy and good power on the second stage. The big negative is that as far as I know there are no jets & metering rods available for performance tuning, so any mixture adjustments required on cruise and power need to be done manually and would be very time consuming. So it was just easier to throw a Weber / Holley on instead. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|