|

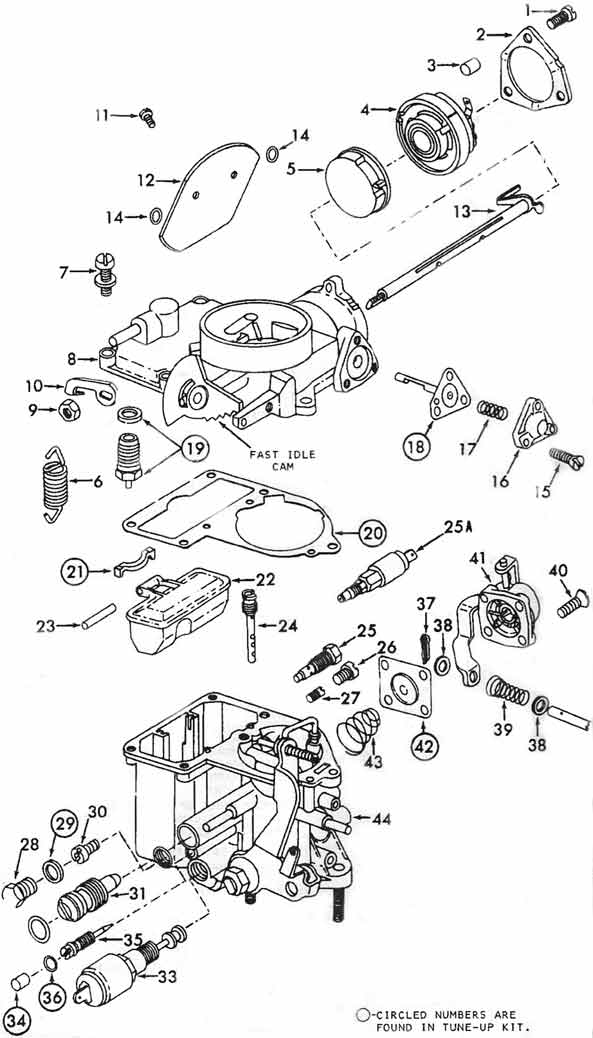

Solex 30PICT-2, -3, 34PICT -3 -4 |

|

This one was fitted to a VW bug. 1968-74 type I , 1968-71 type II. A simple little carb that is very easy to rekit clean and adjust. |

|

Float setting: Proper needle & seat gasket must be used for specific carburettor. Use the following data to determine the gasket required. 30PICT-2 1.0mm 30PICT-3 1.5mm. combine 1.0 & .5 gaskets. 34PICT-3 .5mm I find this data is a generality. I double check the actual float position after installing the recommended washer just to be sure the float level is correct. Using a vernier caliper measure the needle with the gasket in place. Now using this measurement invert the carby body with float installed with the retainer in place #21. Hold the float in position & place vernier exacting where the needle will touch the float & see where the float will sit. I like to set it parallel with the top surface. Use the washers supplied or other washers to obtain the correct level. Adjustment: Initial settings - idle control screw should not touch the fast idle cam at idle with choke off fully. In this model the throttle disc is completely closed at idle. Turn mixture screw #35 in slowly until it stops, then turn out 2.5 to 3 turns. Turn in by-pass screw #31 until it stops then turn out 3 turns. Ensure the by-pass air cut-off solenoid is working correctly (if fitted) by testing it for sound activation. Ignition on remove the electrical connection & refit a few times. You will hear a clicking sound that indicates it is working. Refit the wire & continue. Do the same for the fuel shut-off solenoid #25A (if fitted) Start engine & warm up. Set mixture screw for best idle. From here the correct setting is to turn the mixture screw in so as to drop the idle speed by 20rpm. I prefer to leave it at the best idle & vacuum reading. Reset to correct idle speed by turning the by-pass screw. Repeat mixture setting again to obtain best idle & then reset idle speed. Ensure the timing is correct for your model engine before final carburettor settings. Choke Setting: When the engine starts the choke pull off diaphram #18 will pull the choke off slightly to avoid over-choking. Ensure it does just that. If not then you will need to re-check that it is fitted correctly. You can test how far it will pull the choke off when you fit the diaphram in place before the choke housing goes on. This is simply done by pushing the diaphram shaft into it housing as far as it will travel & check to see that it opens the choke butterfly from the closed position. If it does then the choke housing can be fitted and adjusted. Loosen the screws #1 on the choke housing bracket. Rotate the housing #4 counter-clockwise until the hook on the coil spring contacts the lever on the choke shaft. From here it should only take about an 1/8 of a turn to line up the index marks on the cover. However due to the age this may not be in the correct position anymore. Best way to do it is to bring the hook into contact with the link on the shaft and continue to rotate in a counter clockwise direction untill the butterfly #12 just closes again the airhorn. This should be done in the morning because the temperature changes through-out the day, so if you set it in the middle of the day the choke will be to tight in the morning when the temperature is colder. Although this will not over choke the carby, it will take longer to come off. If you move to a different climate area, you will need to reset the choke again to keep it in optimal adjustment. Now the final fast idle setting. Screw out the idling control screw until you can fit the cam lever onto its third step against the screw. Adjust the screw until it touches the third step and then turn in a further 1/4 turn. Now the way I do it is start the engine from cold & screw the idling control screw in or out to achieve a fast idle of about 1200rpm. end of story. If all else has been adjusted correctly the vehicle should start & run at fast idle when cold and slowly release back to normal idle when the choke releases. The throttle will need to be depressed for the fast idle cam to fall and allow the lever arm to return to its normal closed position otherwise the engine will still rev high even though the choke may be off. Final tips: Linkages can be prone to wear, usually the accelerator pump linkages #41 back to the throttle shaft. Too much movement and you will probably get a hesitation when you hit the accelerator pedal. Float level setting is critical. Spend the time to get it right. |